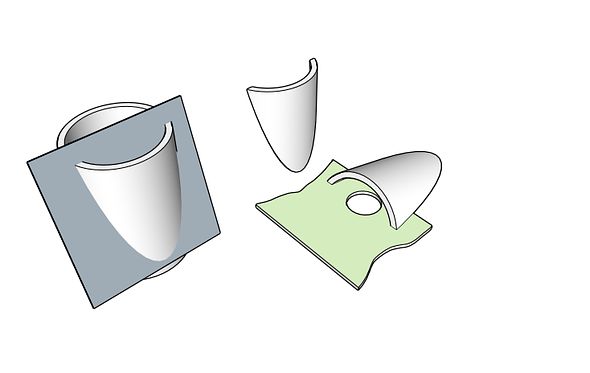

When its time to add the venturi-causing shield over the tunnel vent.... just use a small segment of pipe- has to be about 3" or maybe 4" dia. A sliver off one side that gives a 2" wide by 3-4" long parabolic leading edge w/ a flat trailing edge that about 1/2 covers the vent opening; will create enough low pressure to 'vent' the tunnel and you won't need to have a plate along the entire leading edge of the tunnel's transition to bottom panels.

This pc would mount from CL of the vent pipe through-hull opening (fore & aft) extending to a couple inches forward of the transverse tunnel weld seam along or covering a few inches of the keel seam. All that is needed to avoid the pressure of the wake coming up in the vent is a shroud over the opening that will cavitate at speed and that forms a low pressure area from the bottom of the opening relative to the upper vent opening.

Looks like nice clean cuts, good quality uniform seams that provide nicely formed weld 'grooves'. When welding this- either TIG or MIG, try to avoid the error of stopping or starting a weld bead within 1-1/2" of any corners. The welds should start or stop away from corners in the photo shown, and the beads should wrap those corners while fully heated in the arc. Corners are the sites of stress cracking if the welds are started or stopped on/in them.

Cheers,

Kevin Morin

Kenai, AK